SPECIAL REPORT: How water, electricity rationing hurts concrete blocks dealers -5

INVESTORS in the concrete blocks manufacturing industry are counting losses attributed to regular water rationing and electricity outages.

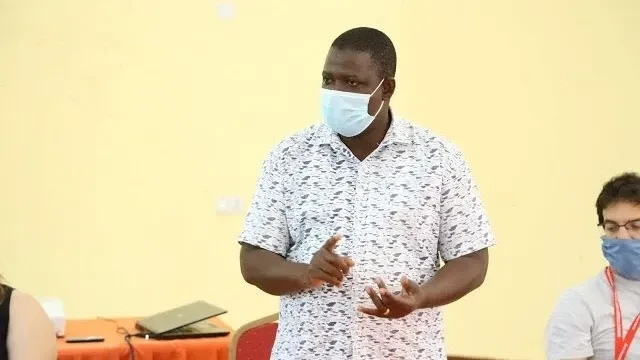

Sedekia Falesi, Manager ADS Hardware and Vibrated Block at Skanska suburb in Dar es Salaam said that he pays between 250,000/- and 300,000/- a month on water bills.

“When there is water rationing I spend 90,000/- for three water containers of 1,000/- liters each on a daily basis. A huge amount of water is needed for preparation of mortar and watering bricks and pelvic stones,” said Falesi.

According to him, operations are stalled during water rationing while the water he buys from private suppliers are used for watering the blocks in morning and evenings.

“I spend a maximum of 400,000/- a month when water rationing is high in the city alongside losing urgent blocks and pelvic stones orders from bulk buyers,” said Falesi.

Speaking of electricity rationing, he said it normally takes between two to eight hours hence incurring him losses of mortar.

According to him, mortar should not be left for over 40 minutes unless cement loses quality of producing good blocks. When mortar gets dry it becomes useless.

“Sometimes power outages occur when mortar is ready for manufacturing the blocks. I sometimes incur a loss of up to 85,000/- in cement that has been mixed with sand due to power outages,” he said.

He said that he pays an eighteen percent Value Added Tax (VAT) on whatever amount of vibrated blocks he sells and for that reason he deserves quality services from the government that will make the business flourish.

Falesi demands on quality government services resonate with Article 8 (1) (b) of the Constitution of the United Republic of Tanzania 1977 which highlights the primary responsibility of the government as being to safeguard the people’s welfare.

However, Article 9 (d) of the same Constitution reads: ‘The state authority and all its agencies are obligated to direct their policies and programmes towards ensuring that the national economy is planned and promoted in a balanced and integrated manner.’

Falesi asserted that he pays 357.14/- per unit of electricity as he pleaded to the Tanzania Electric Supply Company Limited (TANESCO) to cut the price to at least 250/- per unit especially for vibrated block small-scale manufacturers.

Operating under a working capital worth 20mn/-, he spends almost 700 units of electricity a month.

But Judith Kapinga, Energy Deputy Minister said that the price per electricity unit is set according to the costs incurred in production, transportation and distribution activities.

She said the current price is basically not the actual one because it has a government subsidy in it. The subsidy has made the average price of one unit of electricity to be 100/- for end users who consume less than 75 units a month.

Kapinga asserted that a customer who consumes more than 75 units a month pays 292/- per unit of electricity instead of 320/- because the government has also injected a subsidy in the said price.

"Regarding the issue of reducing the price of one unit of electricity, the ministry continues to evaluate the costs of providing services incurred by Tanzania Electric Supply Company Limited and see the possibility of reducing them if proved that it does not affect operational costs," said Kapinga.

Selemani Athumani, Manager Ombeni Hardware Vibrated Blocks in Goba suburb of Dar es Salaam said that water rationing incurs small-scale blocks manufacturing an estimated 270,000/- a month on water for watering blocks and for manufacturing less than 200 blocks a day.

“Water rationing and electricity blackouts are a burden for small-scale vibrated block manufacturers,” said Athumani.

Engineer Mkama Bwire, Acting Chief Executive Officer for Dar es Salaam Water Supply and Sanitation Authority (DAWASA) said water rationing has significantly been cut down by the authority.

He said as of now water cuts do not exceed six hours before the problem that had resulted to such cutting is being fixed and the service resumed to customers.

“As for block manufacturers the authority is considering to start supplying them water treated from sewage instead of supplying them treated water which should be used only for domestic consumptions,” said Bwire.

Related concerns were raised by small-scale vibrated block manufacturers who spoke to this journalist in the towns of Dodoma, Kibaha and Mororgoro.

In her response, Engineer Mwajuma Waziri, Permanent Secretary in the Ministry of Water said that the government has invested in machinery capable of producing 590 million liters on a daily basis, but due to inefficiencies and poor control of water loss, the DAWASA currently produces only 320 million liter.

“The authority sells only 210 million liters on a daily basis with water losses standing at 110 million liters. This loss means the authority could potentially serve an average of six million residents of Dar es Salaam and the Coast region where DAWASA serves,” said Engineer Waziri.

According to her, the 110 million liters lost water is equivalent to 34.37 percent of the current DAWASA’s production.

In addressing the shortage of clean and safe water for all Tanzanians, the PS said that the ministry had in July 2022 launched the third phase of the Water Sector Development Programme (WSDP) which targets at strengthening institutions for integrated water resource management, increasing water supply, sanitation and hygiene services.

Engineer Waziri said the World Bank USD 352 million funded project has so far played a significant role in boosting investments in Tanzania’s water sector, resource mobilization, and capacity building. The project will be implemented countrywide from 2019.

This journalist has established that unreliable access to water jeopardizes the Sustainable Development Goal 6 (SDG6) which targets at ensuring easy access to clean safe water and sanitation for all.

The World Economic Forum (WEF) in its joint report with Oliver Wyman dubbed: ‘Nature Positive: Role of the Cement and Concrete Sector’ released September 2023 states that the concrete and cement sector accounts for nine percent of global industrial water withdrawals.

It states that 75 percent of concrete production by 2050 will occur in regions that are expected to experience water stress.

“In particular, water is used for cooling equipment and exhaust gases, for wet-process kilns which can be almost replaced by more efficient dry-process technologies, for aggregate washing and for the manufacturing of concrete,” reads the WEF report.

WEF asserts that while activities such as agriculture89 demand far more water, concrete production alone is responsible for nine percent of global industrial water withdrawal or 1.7 percent of total global water withdrawal.

“By prioritizing water management, emissions reductions, land stewardship, circularity and innovation, the sector can unlock USD44 billion in additional annual values by 2030,” reads the report.

The Global Cement and Concrete Association’s (GCCA) Sustainability Guidelines for the monitoring and reporting of water in cement manufacturing of November 2018 states that leading companies in the sector already acknowledge their natural footprint and have committed to act.

For example, in September 2021 Holcim launched its new nature strategy that commits the company to contribute to a nature-positive future, with measurable water and biodiversity targets.

It clarifies that as part of its water positive approach to production, Dalmia Cement conserved and harvested 14 times water as it consumed and recycled 31 percent of used water from 2022 to 2023.

The GCCA report states that top four drivers of nature loss in the value chain of the cement and concrete sector are water loss, land-use change and ecosystem disturbance, air pollution and greenhouse gas emissions.

It is explained in the report that the sector withdraws water across its entire value chain. Quarries for sourcing raw materials upstream are usually connected to local freshwater supplies.

GCCA states that most water withdrawal occurs during the midstream production of clinker, cement and concrete.

One of the damages that cement can cause is the waterproofing of the soil, such as the loss of its capacity to infiltrate and retain water.

This can lead to problems of run-off, erosion, flooding, drought, desertification and contamination of surface and groundwater.

Cement consumes almost one-tenth of industrial water use, and 75 percent of this consumption occurs in regions suffering from drought.

The International Energy Agency (IEA) warns that the direct CO2 emissions intensity of cement production has broadly flat over the last five years, and is estimated to have increased slightly by one percent in 2022.

IEA states that in contrast, annual CO2 intensity declines of four percent through to 2030 are required for the sector to get on track with the Net-Zero Emissions by 2050 (NZE) Scenario.

“Reducing of the clinker-to-cement ratio through the uptake of clinker substitutes, continuous energy efficiency improvements, adoption of low-carbon fuels, material efficiency improvements, and deployment of innovative technologies, such as Carbon Capture and Storage (CCS), will play a significant role in achieving the goal,” reads the IEA 2022 report.

It states that the production of one tonne of clinker generates about 0.9 tonnes of CO2, of which 60 percent comes from the calcination of limestone and 40 percent from the combustion of fuels.

Therefore, the production of one tonne of cement, which contains 65 percent clinker on average, generates about 0.6 tonnes of CO2.

The United Nations Environmental Programme (UNEP) is at the forefront of supporting the Paris Agreement goal of keeping global temperature rise well below 2°C, and aiming for 1.5°C, compared to pre-industrial levels.

In realizing this goal, UNEP has developed the ‘Sectoral Solution’, a roadmap to reducing emissions across sectors in line with the Paris Agreement commitments and in pursuit of climate stability.

The six sectors identified are: energy; industry; agriculture and food; forests and land use; transport; and buildings and cities.

Top Headlines

© 2025 IPPMEDIA.COM. ALL RIGHTS RESERVED